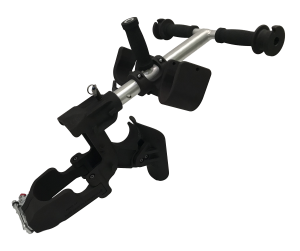

The ExoRam® Standing Tile Removal Tool is used on a Bosch® 11264EVS Chipping Hammer. Features electrical wire and vacuum hose routing guides. Speed up the removal process and dramatically lessen operator fatigue!

The ExoRam® is the professional LIGHT-WEIGHT and rugged solution for removing tile from a standing position. It is just one of many high-quality Dust Free Tile Removal Tools® manufactured by DustRam, LLC for flooring professionals, remodelers, and various other contractors who want to prevent toxic silica dust from filling up a home or business.

The ExoRam® required about 3 years to conceptualize and refine through numerous iterations before the final version was made available for public use or viewing.

The electrical cord from the Bosch® 11264EVS Chipping Hammer (hammer requires the Bosch HS1915 tile chisel) and the vacuum hose from the Nylon DustRam® can be routed on either the left or right side, depending on the needs of the operator.

There are six adjustments in the handle to provide the optimum setting, depending on the height of the operator.

The pivoting Shin/Knee platform allows the operator to change angles of the ExoRam®, while still maintaining the leverage to exert additional pressure. This speeds the removal process dramatically.

Compare the ExoRam® to a standing device on the market known as the HHDA™ DemoSled™, which requires mounting the chipping hammer upside-down. This causes all sorts of mechanical issues down the road.

In the upside-down position, when the chipping hammer reaches operating temperature the grease inside becomes liquefied and flows away from the gears, including other vital moving parts. This issue can cause numerous issues and leads to accelerated wear meaning more equipment downtime and repair costs.

Here is an instructional video on how to mount an ExoRam®, SkiRam®, DustRam®, and ChipRam® to a Bosch® 11264EVS Chipping Hammer.

For more information and to watch videos on how the competitors’ products perform on real job applications, click here.

Front view of the ExoRam® showing the quick-release toggle latch for easy attachment to a Bosch® 11264EVS and the quick-release T-handle push pin. These features make it easy to use the ExoRam® and convert the chipping hammer quickly from standing to kneeling in a matter of seconds.

The other downfall of the HHDA™ DemoSled™ is it is very difficult to assemble and disassemble to the chipping hammer. Once assembled, the chipping hammer is no longer useful in small compact areas, such as pantries, bathrooms, closets, and tiny kitchens. This now requires the additional purchase of another chipping hammer to be operated in those smaller areas.

The competitor’s stand up device does not offer a fast way to change the setting for the length of the handle. It requires the use of tools, which are not convenient to carry around. This feature does not permit the easy use of the device by operators who are of differing heights.

Additionally, the competitor’s stand up device is very heavy and cumbersome to use. The knee placement pad is too small for bigger/taller operators; if the operator is too tall their knee will actually hit the metal part above the knee pad. This is very painful!

In contrast, the ExoRam® can literally be mounted to the chipping hammer in about 3 seconds and removed in about 3 seconds. ALL of this convenience without the need of a single additional tool for assembly or disassembly. It also eliminates the need for a separate chipping hammer to use in compact areas. Bonuses…all of this!

The ExoRam® allows changing handle adjustments quickly and on the fly, requiring the simple push of a button on the T-handle, pulling the push-pin out, selecting the desired setting, and push the button on the T-handle and insert the push-pin back into the hole. The whole process takes about 10 seconds.

The ExoRam® is much lighter than the competitors, weighing in at 9.6 pounds, with the competitor at 17 pounds. This means the ExoRam® is 177% lighter than the competition.

The team at Arizona Home Floors put the ExoRam® through grueling and vigorous removal processes of all types, ranging from simple ceramic and porcelain, and including the more difficult types of Saltillo, Slate, and Travertine.

When working in large open areas the ExoRam® can double or triple the amount of square footage, which can be broke free from the mortar or thinset bed, as opposed to crawling on your knees.

Once the old flooring has been removed, the ExoRam® becomes instrumental in removing unusually thick mortar or thinset beds quicker than trying to grind it off. The team at Arizona Home Floors has found using the ExoRam® along with a ChipRam® on mortar beds thicker than 1/2″ is the most effective process for removal.

This process creates “grooves” in the mortar bed, which allow your grinding wheels to become more aggressive at removing the balance of the thinset or mortar. Using this method, it is not necessary to chip every square inch of the thinset bed.

To purchase a ExoRam® will require the purchaser to complete an NDA prior to the sale or shipment of equipment.

Here is a video showing the ExoRam® being used with our Nylon DustRam®:

Contact our office at (480) 428-3880 for more information on the various pieces of tile removal tools & equipment or to learn about DustRam assigned territories for your company.