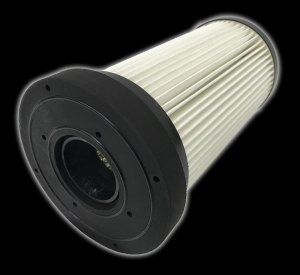

PulseRam® Filter shown here with the optional 3D Printed PulseRam® Filter Adapter Plate/O-Rings manufactured by DustRam, LLC. Both the Filter and Adapter fits the CDCLarue® Pulse-Bac 1000, Pro, and HPLM Series Vacuums.

DustRam, LLC has a filter specifically designed for the PulseRam® vacuum and the performance needed for the rigorous demands of dust free tile removal.

Additionally, this filter is also backward compatible with *CDCLarue® *Pulse-Bac® filters for Vacuums Models: PB-1050H, PB-1050, PB-1150, PB-1250, Pro-176, Pro-225, Pro-311, HPLM-2450, HPLM-2450D, HPLM-3690, and HPLM-3690D.

A brief history is in order to explain why a filter for the PulseRam®, which also retrofits to various CDCLarue® Pulse-Bac® vacuums became necessary to develop.

Sometime around 2007, Jack King, owner of Arizona Home Floors, LLC first purchased a PB-1250 vacuum from CDCLarue®, then within a few weeks purchased another.

A relationship of sorts developed through the years, and along the way King started DustRam, LLC and began to develop various chipping hammer accessories, building the market for dust free tile removal, including preparing for the strict OSHA silica dust requirements yet to come.

Below is an instructional video on what to look for if your existing Pulse-Bac filter plates begin to crack and allow dust to migrate through the threads. Also shown in this video is the proper way to replace your filters.

For several years, King enlisted several other contractors throughout the country to become “DustRam® Contractors” and to purchase various tools, vacuums, and accessories that make up the DustRam® System. Between King and those other contractors, dozens of PB-1250 vacuums had been purchased and were used as one of the components in the DustRam® System. Please note a full DustRam® System typically has 250+ components.

It was not long before King realized how hard it was on these vacuums, including its components to pick up literally hundreds of pounds of coarse debris and dust in as little as 1 hour of use. It became important to maximize the vacuums up-time and performance to keep up with the dustless tile removal process.

King made a few suggestions on ways to improve reliability and performance but no one seemed interested in the message. As the DustRam® contractors looked to King to provide answers to questions they had about their vacuums, DustRam, LLC began manufacturing solutions to overcome any obstacles encountered. The PulseRam® filter is one of several manufacturing and performance solutions designed to fit many of the CDCLarue® vacuums they have on the market.

A brand new CDCLarue® Pulse-Bac® filter showing wider portion of the base not completely “potted” into the epoxy, resulting in filter pleats not fully sealed during use. Has this happened to you?

Developing the PulseRam® filter became necessary ONLY after several instances of the Pulse-Bac® filter base (the part of the filter that contains the coarse threads for installation), becoming separated from the pleats. Upon closer scrutiny, it was discovered that on some of the filters purchased the pleats had not been fully embedded into the epoxy potting material.

This resulted in dust leaking through the incomplete epoxy seal, and damage to the interior components of the vacuums. This event required a complete tear-down, deep cleaning and rebuild of the vacuum. This was both costly, time-consuming, and aggravating as shown in the video at the bottom of this page.

Notice the picture of a red CDCLarue® filter base that became separated from the pleats. Opening the picture in a new window shows the epoxy potting material barely touched the pleats. Had this filter been accidentally installed on a vacuum would have resulted in dust circulating throughout all the sensitive components, such as the solenoids, electric motor brushes, and electric motor armature.

During the design phase of the PulseRam® filter, King looked for ways to enhance the performance and airflow as it pertained to the dust free tile removal process. From his extensive experience with removing tile and thinset, King knew coarse debris and grit are the norms when performing dustless flooring removal, it became necessary to reduce the number of pleats, thereby making the pleats wider to allow the vacuum an easier way to dislodge the larger pieces from the HEPA pleats.

Below is a table to provide additional technical information.

DustRam, LLC has solved the issues of airflow and pleats separating from the base of the PulseBac® filters.| Physical Comparisons Between A PulseRam® Filter and A CDCLarue® Pulse-Bac® Filter | PulseRam® Filter | CDCLarue® Pulse-Bac® Filter |

|---|---|---|

| Approximate Number of Pleats | 60 | 77 |

| Approximate Depth of Pleats | 1.25" | 7/8" |

| Approximate Square Feet of Filter Media | 8.46 sq. ft. = 10.16% more than Pulse-Bac® Filter | 7.60 sq. ft. = 10.16% less than PulseRam® Filter |

| Approximate Filter Seal Thickness | Approximately 3/16" | Approximately 1/16" |

| Filter Seal Integrated to Filter Base? | Yes | No |

| Filter Base Designed To Aid In Developing A Full Seal? | Yes, a 100% flat base from the outside edge to the inner edge promotes a dust free seal provided the stock CDCLarue® Filter Adapter Plates are not cracked from age and wear. | No, gaps and open grooves are molded into the CDCLarue® Filter Base allowing dust to migrate where it should not. |

| Filter Media HEPA Rating | 99.97% @ .3 microns or larger | 99.97% @ .3 microns or larger |

| PulseRam® Filter Fits CDCLarue® PulseBac® Vacuum Models: PB-1050H, PB-1050, PB-1150, PB-1250, Pro-176, Pro-225, Pro-311, HPLM-2450, HPLM-2450D, HPLM-3690, HPLM-3690D |

||

There was plenty of room in the interior of the filter to increase the depth, so the pleats were made much longer than those used in the CDCLarue® filter pleats. In fact, the pleats on the PulseRam filter are about 30% longer.

A PulseRam® Filter with solid 3/16″ thick seal, which is fully adhered to the filter base. The threads shown are backward compatible with most CDCLarue® Pulse-Bac® vacuums.

The PulseRam® filter also contains overall a little more than 10% ADDITIONAL filter media as compared to the CDCLarue® Pulse-Bac® filter, even though the PulseRam® filter only has about 60 pleats (this is an advantage with dealing with coarse debris) and the CDCLarue® filter has about 77 pleats (this is a disadvantage when dealing with coarse debris).

The frustum shaped filter design utilized by CDCLarue® also presents issues when dealing with coarse material. With 77 pleats meeting at the bottom of their filter and confined into a very small area roughly 4″ in diameter, this feature while unique does not allow an easy time for the debris to dislodge from the pleats during the pulsing cycles.

When dealing with small chips of thinset, tile, saltillo, stone, slate, and other items it is important to realize not everything sucked through the vacuum hose will be soft, fluffy dust. Coarse debris has to be recognized, considered and dealt with.

King is confident the PulseRam® filter will handle a higher volume of dust and debris, allowing a higher CFM to be maintained over difficult periods of use such as grinding thinset and saltillo removal. If other additional vacuum modifications are utilized such as using a PulseRam® circuit board that pulses every 5 seconds an even higher increase of performance and reliability can be realized.

To purchase PulseRam® filters will require the purchaser to complete an NDA prior to the sale or shipment of equipment or accessories.

Call NOW to purchase the PulseRam® Filters manufactured by DustRam, LLC at (480) 428-3880 that will also fit CDCLarue® Pulse-Bac® Vacuums

Below is an instructional video on how to convert your existing CDCLarue® filter plates with cracks to the 3D printed DustRam, LLC filter plates.

Below is the video sent to CDCLarue® after King was frustrated with repeatedly cleaning his vacuums caused by defective Pulse Bac® filters.

Other DustRam Products you may be interested in:

We initially made the Nylon DustRam® for usage on vertical surfaces and also floor covering materials.

After numerous hours of screening, it was discovered the Nylon DustRam ® works very well on well-bonded floors and is almost as strong as the steel version.

Use the Nylon DustRam® on a Bosch 11264EVS 1-5/8 SDS-Max Combination Hammer with an HS1915 2 In. x 12 In. SDS-max Tile Chisel for the purposes of removing all types of tile, porcelain, stone, saltillo, tackstrip, thinset, stacked stone, showers, and countertops; faster, cleaner, and quicker than you can imagine.

Click HERE to learn more about purchasing a Nylon DustRam®

The long-awaited ExoRam® device to permit the operator to stand while removing ceramic tile, porcelain, saltillo, slate, travertine, as well as other floor covering products is currently readily available for purchase.

Click HERE to learn more about purchasing an ExoRam®.

Here is a unique 3D printed piece of equipment manufactured by DustRam, LLC called the SkiRam®. This device when mounted will allow your Bosch® 11264EVS 1-5/8 SDS-Max Combination Hammer to stand upright when not in use.

Click HERE to learn more about purchasing a SkiRam®.

For contractors everywhere who struggle to edge along baseboards and under toe-kicks, DustRam LLC has the solution for you. This premium dust free grinding shroud is like no other on the market.

Click HERE to learn more about purchasing a Small EdgeRam®.

After working out some of the issues we and our contractors experienced with the red filters made by CDCLarue® we ended up creating our own backward compatible solution for the vacuum models: PB-1050H, PB-1050, PB-1150, PB-1250, Pro-176, Pro-225, Pro-311, HPLM-2450, HPLM-2450D, HPLM-3690, and HPLM-3690D

Visit the link above to see if your vacuum is included in the list or Click HERE to learn more about purchasing PulseRam® Filters for your CDCLarue Vacuums®.

3D Printed Filter Plates For The Pulse-Bac® Vacuum 1250 And All 1000 Series

CDCLarue® Pulse-Bac® replacement filter plates are available now to replace the original ones that came with your vacuum. The filter plates we manufacture are backward compatible with these vacuums: PB-1050H, PB-1050, PB-1150, PB-1250, Pro-176, Pro-225, Pro-311, HPLM-2450, HPLM-2450D, HPLM-3690, and HPLM-3690D

Visit the page by clicking on the link above, or call us at (480) 428-3880 to learn more. Have your model number double checked before you call to ensure compatibility.

Are you having problems getting your filters to clean properly on your *CDCLarue® *PulseBac® vacuums? If so, DustRam, LLC has a solution you might want to check out.

Click HERE to learn more about purchasing a PulseRam® Circuit Board.

Pulse-Bac® Upgraded Solenoid Bolt & Pin For CDCLarue® 1000 Series Vacuums manufactured by DustRam, LLC. Please Note: Solenoid is sold separately.

Pulse-Bac® Upgraded Solenoid Bolt & Pin For CDCLarue® 1000 Series Vacuums

Click HERE to learn more about purchasing PulseRam® Filters for your CDCLarue Vacuums®.

The VacRam® was designed by DustRam, LLC to help speed the process of vacuuming coarse debris from the floor during the many stages of the tile removal process.

Click HERE to learn more about purchasing a VacRam®.

*Disclaimer: Pulse-Bac® and CDCLarue® are registered trademarks of Christy Inc. Please Note: DustRam, LLC does not sell, distribute or manufacture Pulse-Bac® vacuums or distribute CDCLarue® manufactured parts. However, DustRam, LLC does manufacture certain aftermarket performance products, which can fit certain models of their vacuums.

For OEM Pulse-Bac® parts visit https://www.pulsebac.com/